DurAMat

“Sustainable production, processing and modelling of durable additive manufactured materials for enhanced performance and long-term service in complex environments.”

A game-changer in material science is making its way into society!

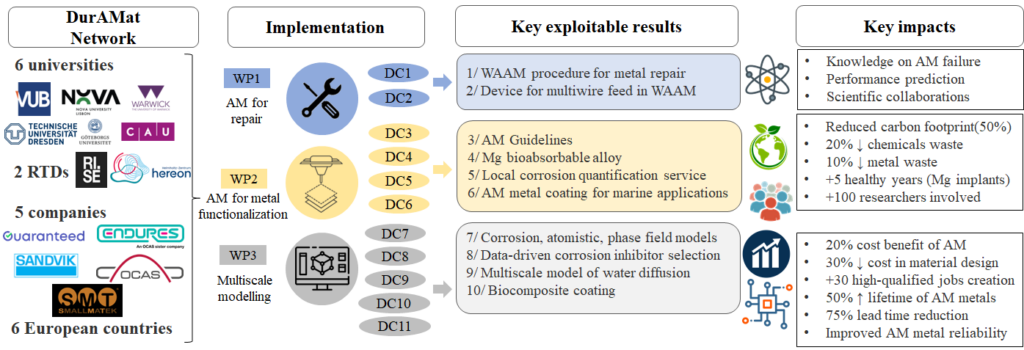

The project DurAMat will put an end to the slow uptake of new and sustainable materials in the most diverse spread of industries, ranging from the energy to the medical sectors. The key aspect of DurAMat is the focus on severe exposure environments. With DurAMat, additively manufactured (AM) metal products will be ready to pave the road of the future by developing truly sustainable AM components from different metal alloy families.

The project further aims to see an end to defunct metallic products by developing preferred repair methods using AM, and beyond that, enable AM functionalisation. Just to mention some of the remarkable forecasts, there will be a 30% energy reduction in the processing and manufacturing of products, 60% less end-product failures reducing health hazards, eco pollution and casualties, and a 20% cost-benefit compared to conventional industry approaches.

Experimental research paired with multiscale computational modelling and machine learning methods will fill in the knowledge gaps and help innovate. The list of innovations is outstanding: from AM metals and coatings to new technologies and services.

DurAMat is six universities, two research centres and six industrial companies strong. The members are from six European countries; they have created a brand-new and original training programme using a holistic and cross disciplinary approach. Eleven doctoral candidates will benefit from the experience of top researchers in their fields. They will be trained to not only create high research impact but will also cultivate interpersonal and transferable skills.

Meet the creators of DurAMat’s research and training programme.

Vrije Universiteit Brussel’s team in Belgium, Iris De Graeve, Herman Terryn, Reynier Revilla and Fatma Demir are the driving force coordinating the DurAMat collaboration. They are joined by four partners from the academic sector: João Pedro Oliveira from NOVA University of Lisbon in Portugal, Mohsen Mirkhalaf from University of Gothenburg in Sweden, Axel Voigt from Technische Universität Dresden in Germany, and the University of Warwick (UK), as Associate Partner of the DurAMat Project, is represented by James Kermode and Peter Brommer.

Two cutting edge research institutes participate in DurAMat’s beneficiary team, with Mikhail Zheludkevich, Sviatlana Lamaka and Christian Feiler from Germany’s Helmholtz-Zentrum HEREON (in conjunction with the Christian-Albert University of Kiel for the PhD award), and Dominique Thierry from RISE in Sweden.

An impressive array of collaborating industrial partners are the proof of the urgency and validity of DurAMat’s research concept and training programme. They are GUARANTEED, OCAS and ELSYCA from Belgium; SANDVIK from Sweden; SMALLMATEK from Portugal and ENDURES from The Netherlands. The companies will impart know-how and secondment training.

The overseers of the research and training programme, who make up the external advisory board, are experts from BASF Coatings GmbH Germany, TWI in the UK, LABORELEC in Belgium, CIDETEC Surface Engineering in Spain, University of Bergamo in Italy, CORTRONIK in Germany, and Technische Universiteit Delft in The Netherlands. Beyond their role of safeguarding the research progress, they are also expected to mentor the budding researchers.